Blown film extrusion is the oldest film manufacturing process. The molten plastic is ejected from the annular nozzle to form bubbles 10-20 meters high. Then, a pair of pinch rollers put the solidified hoses together. This produces what is called tiling, which extends all the way to the winder. At a point in front of the two winding points, the blade cuts the flat side, causing the two flat films to be wound at the same time.

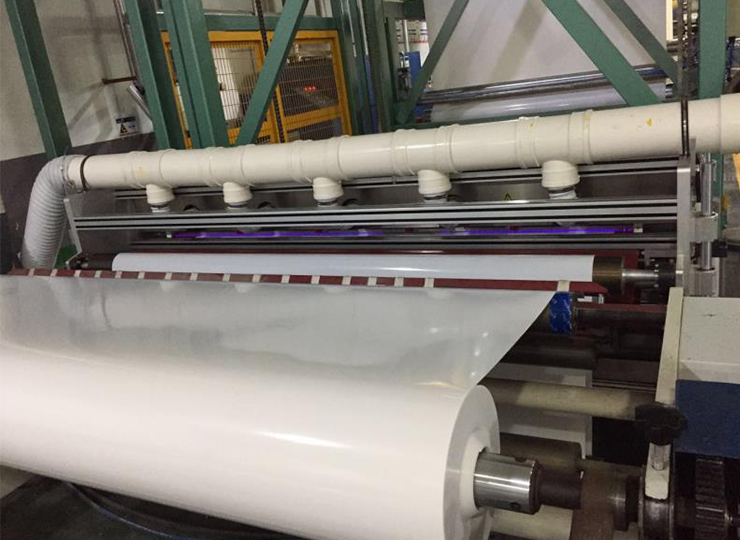

Classic works on extruder

Corona pretreatment laid a valuable foundation for further processing of blown film. Qipu corona system is a classic work of film blowing extruder. Qipu electrostatic has always been committed to meet various needs of customers, and constantly improve and innovate our operating system, aiming to provide customers with reliable corona system and mature customized services. The easy-to-use and stable design makes the Qipu corona system a reliable part of the extruder. For example, the system is protected from loss due to film thickening by the rotational swing of the electrodes.

Blown film extrusion and corona

In the simplest case, the corona treatment of blown film is directly after the flattening of the newly extruded tube, and two rolls of flat film with single side treatment are obtained. However, many applications require treatment of both sides of the film. For example, to print a film.

Pretreatment of four sides on blown film

Therefore, the second side must be treated before winding. After treatment, the film has polarity and the tension expands.

Qipu corona system provides different solutions for different extruders:

1. Two double-sided corona stations are used to process all four flat film sides after cutting.

2. The two outer sides of the plane shall be treated by the double-sided corona table before cutting. Two single sided systems handle both inside of the hose after cutting and before winding.

Shanghai hq electrostatic technology co., LTD. All rights reserved ![]() 沪ICP备11041002号

沪ICP备11041002号  沪公网安备 31011702001800号

沪公网安备 31011702001800号